On the second floor of The Martin Agency’s Shockoe Bottom headquarters, there’s a small, glass-encased room known as the “lab.” This is where you’ll find creative technologist Jeff MacDonald working on some of Martin’s more advanced projects.

“We kind of work in this space of being advertisers as well as inventors,” says MacDonald. “We try to bring something that’s additive to consumers’ lives beyond the disruptive media of advertising.”

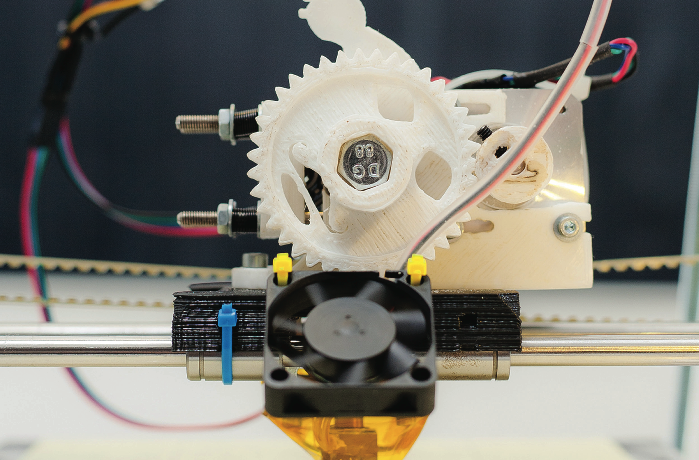

And at the center of this space is the company’s Makerbot Replicator 2, a type of desktop 3D printer. It’s about the size of a microwave and at

first glance appears to be nothing more than an open metal frame, a build platform, and a nozzle mechanism that moves along the x, y, and z-axes. For $2200, it doesn’t look like much when it’s just sitting there, which is surprising since it’s one of the most amazing pieces of consumer-level technology to hit the market in the last decade.

For the uninitiated, a 3D printer builds three-dimensional objects according to a computer-drafted model. The nozzle acts like a hot glue gun that moves along a grid, melting and extruding layer after layer of a spool-fed plastic material until the object is constructed. Depending on what you’re printing and the quality you’re after, build times can take anywhere from 15 minutes to 15 hours, with the result being a lightweight and durable physical rendering of an idea that, before, was nothing more than pixels arranged on a computer screen. If the product you’re making requires the use of plastic, you may enlist the expertise of an injection moulding expert from an injection moulding company to create an accurate 3D model.

Or, as MacDonald puts it, “It makes stuff out of thin air, basically.” It doesn’t take an engineer to see how this technology can help a company like The Martin Agency. The ability to prototype a concept immediately is a massive advantage when pitching ideas to clients. But what makes Martin’s 3D printing operation notable isn’t the way they’re using it to help their own business, but to help others.

Over the course of the past year or so, Jeff MacDonald has become a bona fide subject matter expert in the field (he even moonlights as a pro- fessor at his alma mater, the VCU Brandcenter, introducing the next crop of creative technologists to the marvels of 3D printing). Along the way, he and his colleagues noticed there weren’t many options available to those who

might be interested in learning more about this fascinating and nascent technology. What they saw was an opportunity to educate the masses while extending a service to those who don’t have immediate access to a printer of their own.

“There aren’t a lot of people who are 3D printing right now,” MacDonald explains. “There might be some who have their own printers for personal use, but we’re one of the first groups putting themselves out there saying ‘Hey, if you’ve got something really cool, send it our way and we can see about how to get it printed.’ I’m actually really surprised we’re not seeing more business popping up that offer 3D printing services.” Well, MacDonald, can be quite right. There seem to be only a few businesses that offer 3D printing. However, you might be able to find such companies perhaps, by doing searches similar to “There you have it 3d printing Los Angeles“, or elsewhere, should you need 3D printing done.

What Jeff MacDonald hopes to establish in the coming months is an outreach program that brings individuals, hobbyists, small business owners-“Anyone who’s in the business of making things or imagining what tomorrow looks like,” as he puts it-into Martin for workshops on the basics of 3D printing, from rendering a CAD drawing to completing the finished product. It’s a fitting model considering the collaborative nature that already exists among the 3D printing community. Sites like Thingiverse offer a free and open forum to exchange ideas, download build plans and find answers to problems. MacDonald wants to bring that level of interaction from the digital space into the analog world, which, when you think about it, is kind of the whole point of 3D printing in the first place.

Nearby at the Virginia Biotechnology Research Park, Health Diagnostic Laboratory, Inc. is putting their 3D printer to good use as well. The local disease management company, which offers a panel of tests that can identify risk factors for heart disease and diabetes, keeps their 3D printers buzzing at all times. “We’re using our 3D printers for everything from cost saving measures to building new models that can improve efficiencies in the lab,” explains J. Michael Woodard, chief technology officer at HDL, Inc.

Woodard, who is in a position to see the latest and greatest in technology while working at the largest specialty lab in the country, is quick to point to a modified test tub rack that his team created as an example of the practical utility of having in-house 3D printers. “We have engineering minds, so our 3D printers help us test out ideas and then bring those ideas to fruition.”He concludes, “I find that as a group we’re all com- ing up with more and more ideas now that we have a better way to implement them. We’re making real world stuff.”